How To Measure V Band Clamp

Clamps rarely go their spot in the limelight, yet in the instance of the humble V-ring clamp, the device has seen service in everything from common street cars to NASA spaceflight vehicles. A Five-Band clamp even held the atomic bomb in transport aboard the Enola Gay bomber on information technology'southward flight into history that ended WWII.

Clamps rarely go their spot in the limelight, yet in the instance of the humble V-ring clamp, the device has seen service in everything from common street cars to NASA spaceflight vehicles. A Five-Band clamp even held the atomic bomb in transport aboard the Enola Gay bomber on information technology'southward flight into history that ended WWII.

The humble V-Ring clamp has played a meaning office in history having held the atomic bomb aboard the Enola Gay as it traveled to Nihon ending Earth War 2 and clamping the booster rockets on the John Glen'due south Friendship 7 spacecraft as information technology launched to orbit the earth.

The humble V-Ring clamp has played a meaning office in history having held the atomic bomb aboard the Enola Gay as it traveled to Nihon ending Earth War 2 and clamping the booster rockets on the John Glen'due south Friendship 7 spacecraft as information technology launched to orbit the earth.

V-band clamps can be used to hold most whatsoever flanged joints together. From light duty to the almost enervating purpose, these clamps are produced in a broad range of materials for any application that requires a leak-free, piece of cake to use restraint device.

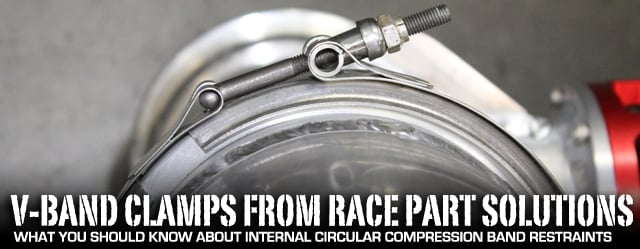

These amazing fasteners can be used to hold well-nigh any flanged joints together. From light duty to the most demanding purpose, these clamps are produced in a wide range of materials for any awarding that requires a leak-free, easy to use restraint device. We reached out to our friends at Race Part Solutions to discover the science backside these sealing devices.

History Of The Five-Band Clamp Inventor

Herbert "Zeppo" Marx, inventor and company owner. His marman clamps have been used by military, racing and aerospace agencies for decades.

Zeppo, the youngest of the Marx brothers, was always bandage in the directly man part. Reportedly frustrated that he couldn't be funny, he left the group after just 5 films to join older brother Gummo in running a talent agency.

In addition to his office every bit an amanuensis, He also was active in engineering, establishing Marman Products Visitor, Inc. of Inglewood, California.

After founding Marman Products in 1941, which made these clamping devices, he held three patents, two of which pertained to his invention of a watch that monitored the pulse of heart patients. This business concern made Zeppo a multimillionaire.

How V-Band Clamps Work

5-band clamps take proven themselves in racing applications from the Indianapolis 500 to Bonneville state speed cars becoming the preferred connectedness for many turbo-housings. They are an excellent option for any exhaust or intake arrangement.

While they come in many different configurations and styles, their main chore is to join tubing, piping and other enclosures. A cantankerous-view of the flange articulation shows how the portion of the coupling that wedges the flanges together in a leakproof seal. The strength of the coupling is determined partly past the servant thickness, the shape of the flange and the material.

Left: This cantankerous view of the coupling shows how the clamping force is practical in a wedging action by the clamp's 'Five' blueprint. Right: Equally torque is applied to the fastening nut, radial force is practical evenly effectually the coupling's flange.

"V-Band clamps are basically a positive attachment retention organisation for tubing and components," said Rob Stevenson of Race Function Solutions' tech back up team.

V-Band clamps are basically a positive attachment memory system for tubing and components. – Rob Stevenson

Equally torque is applied to the nut of the coupling, the retainer applies an inward radial strength compressing the flange together. Unlike bolted flanges, the retainer applies a uniform and equal endmost forcefulness around the entire circumference of the flange during and afterwards tightening.

Once tightened, friction betwixt the flanges and V-servant actually helps reduce the load on the bolt and clamp.

These clamps can exist used to concur together virtually whatsoever flanged joint. Mutual applications range from lite to heavy duty and include diesel engines, turbochargers, pumps, filter vessels, tubing and countless other flanged items.

Types of V-band Clamps

One of the most important aspects of selecting a 5-band clamp is the latch style used in the coupling device. There are several latch styles available, with each one facilitating certain needs. Before selecting a latch manner, the user should know how oftentimes the coupling will be removed and reassembled and what pressure the application is under. Race Part Soulutions are known for acme quality V-Band assemblies and replacement parts with aluminum, steel and stainless steel versions available.

Latch Styles:

Race Part Solutions offers V-Band clamps with the standard T-Commodities and Trunion style latches or the T-Bolt quick release style latches.

T-Bolt and Trunnion – The T-commodities and Trunnion latch is perfect for those applications when the clench is not going to exist removed frequently. This latch is ane of the strongest available and will piece of work on any sized coupling.

T-Commodities and Trunnion latch

T-bolt quick release – If the clamp is going to exist opened frequently, the T-bolt quick release latch can exist quickly opened by loosening the nut and raising the hinged latch. They likewise work on any sized coupling and allow the operator to supervene upon the T-bolt if necessary.

T-Bolt Quick Release Latch

Retainers

As far as the retainers go, there are 2 types of servant styles. There are V-ring couplings and 5-ring retainers although both styles are typically called V-band clamps. The V-band couplings are made from multiple V-segments spot-welded to a canvass-metal band, whereas the Five-ring retainer is made from a single V-segment welded to a band. The V-band coupling has the advantage of less distortion on the flange if the band is over-tightened.

"Even as circuitous as these clamps are, they are relatively inexpensive when compared to anything else out there that does the same chore," Stevenson reminded united states of america.

5-Ring Flanges

There are two basic types of 5-band flanges available, bulge-formed and machined. The burl-formed flanges are formed from a tube that is "bulged" so collapsed to course a apartment flange. Machined flanges are machined from metal stock. Machined flanges should be used with a gasket for most connections. The bulge-formed flanges are typically lighter than machined flanges and the thinner department of the flange is closer in thickness to the base tube resulting in a more compliant joint. This helps minimize stress cracking in the weld.

One of the advantages of using a V-Band clamp is that these retainers are perfect for applications requiring frequent removal. They provide a quicker disassembly yet provide a not bad seal with even force per unit area at the flange.

Advantages of V-band Clamps

When compared to 2 or three-bolt flanges, the V-ring connections are lighter, quicker and easier to take autonomously. In near cases the V-band clamps are economical when you lot consider the cost of time in installation and reassembly. V-ring connections require a smaller fitment envelope every bit compared with multi-bolt flanges, and the biggest reward, the design of the 5-ring clench applies uniform force around the flange which maximizes the seal potential of the flanges. Stevenson says, "The biggest advantage with Five-band clamps in racing is that it is a quick method of attaching components. They can greatly meliorate maintenance time betwixt rounds during a race when yous need to become a lot of parts taken off and put back on rapidly."

- Reduces assembly cost, saves time and ease of accessibility

- Platonic for applications requiring frequent access for cleaning, inspection or replacement of internal components

- Smaller envelop dimensions, weight savings and improved advent

- Provides boosted strength past arresting circumferential load

Exercise's and Don'ts

According to Stevenson, "One of the biggest practise's in regards to Five-ring clamps is using a drib of anti-sieze on the clamp's retaining nut. This helps extend the life of the clench and protects the ability of the fastener, which may diminish over time."

- Exercise make sure that whatsoever pressure in the system is released earlier unfastening coupler.

- Exercise glaze the inside of the retainers with dry pic lubricant to reduce friction betwixt the coupling and the flanges.

- Do not use aluminum in applications over 400°F

- Do not utilise titanium in applications over 600°F

- Practise not use stainless steel in applications over 800°F

- Practise not employ A286 in applications over 1,000°F

- Do not utilise nickel 718 for applications over 1,200°F

Installation

For a V-band clamp to work optimally, proper installation is disquisitional. Tubes and components of the coupling must be joined and aligned before installing the coupling. The flanges must too be aligned correctly prior to coupling installation for good joint performance.

The V-Band clamp, with information technology's simple design, provides a groovy seal at the coupling with even strength applied around the entire radius of the clamp. Information technology'south a must have item on race cars using big tubing for induction or power adders.

If the V-band couplings have multiple segments, each segment must have the V-shaped groove fitted onto the flange. Ensure that the retainer does not bottom out on the flange before reaching the required loading. Tighten nut.

Tighten the nut to approximately seventy% of the required torque (on double-latch assemblies, torque both latches equally). Check to assure the coupling has seated over flanges equally around the periphery. Also, check for correct flange alignment. Radial flange alignment tin be checked visually in the gap between adjacent retainer segments.

Every 5-band coupling has a minimum torque value, dependent on the fastener or T-bolt size. The installation process should include torquing the latch to it'south proper torque value, and then seating the coupling and re-torquing the coupling until the torque value is stable. For instance, a common torque value instance would be 45- inch pounds. Torque the latch to 70% of the terminal torque (31-inch pounds) then tap the coupling with a rubber mallet. After seating the coupling, increase torque to 100% of the specified value, lightly tap effectually the outer periphery equally necessary to prevent unequal loading. Torque the latch to the final torque value again. Repeat these steps until torque does not motion the retaining nut.

This ensures a skilful fit at the union, does not stretch the clamp, and does not over-stress the union causing cracks and early on failure. Prophylactic-wire the latch if applicative.

Tips and tricks

- Coating the inside of the retainers with dry-film lubricants helps reduce friction betwixt the coupling and flanges.

- Dry-film lubricants are too recommended for T-bolt threads to reduce galling and extend thread life.

- Dry lubricants as well help in applying the true torque to the coupling, which contributes to proper joint performance, especially in high-vibration applications.

There are various sizes and styles of V-band clamps available from Race Parts Solutions, and one trip to their website tin can get you lot started in the right direction for your functioning clamp needs.

Source: https://www.enginelabs.com/engine-tech/exhaust/v-band-clamps-from-race-parts-solutions/

0 Response to "How To Measure V Band Clamp"

Post a Comment